Table Of Content

Fans of different types and even fans of the same type, but supplied by different manufacturers, do not necessarily react to a system in the same way. Therefore, judgment based on experience must be applied to any design. Dynamic loss is based on the actual velocity in the duct, not the velocity in an equivalent circular duct. For the cross section to reference a fitting loss coefficient, see step 5 in the section on HVAC Duct Design Procedures. Where necessary (e.g., unequal-area fittings), convert a loss coefficient from section o to section 1 using Equation (31), where V is the velocity at the respective sections. Basically, you need the duct to be tall enough to open a duct collar for a flexible duct connection.

Ready to start a project?

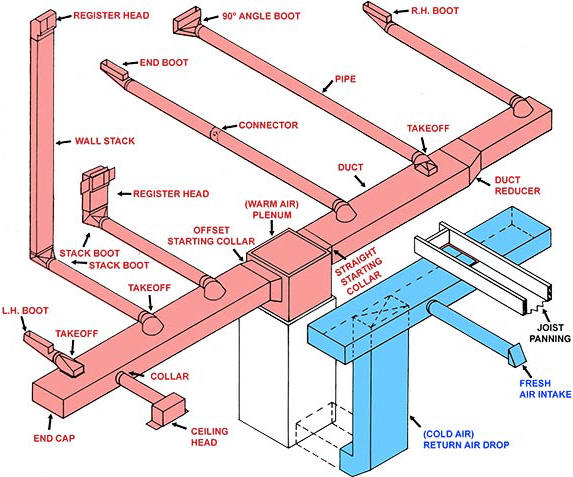

Once you know how many BTUs your house is gaining, you can purchase the correct sized air conditioner. Supply ducts should be located on outside walls, preferably under windows and near doors. The intent is to wash the exterior walls with heated or cooled air. Drywall that is nailed to 2x4s is really a duct - a box with 4 sides. All you have to do is cut out the floor immediately below the wall cavity as well as the bottom wall plate. Once you have created the opening, sheet metal will allow you to connect this to your existing return air system.

No Air Blowing From the Vents in Your Home? Here’s What to Do

Each type of ductwork creates friction loss as the air moves through it. Flat sheet metal ductwork is the smoothest – causes the least friction loss. Flex duct creates the most friction loss, and importantly, when it isn’t stretched tight, it might create an unacceptable amount of friction. At 900 L/s flow in section 1, 130 Pa imbalance remains at the junction of sections 1 and 4.

BERNOULLI EQUATION

Meanwhile, bedroom 2 and bedroom 3 only have 2 linear diffusers respectively. Hence, air can flow from one side of the room to the other side of the room instead of short cycling itself which can lead to all sorts of cooling problems. Yu is an HVAC professional with over 10 years of experience. He design, install, commission and service various kind of HVAC systems.

Getting HVAC Right: Consider These Tips When Sizing and Specifying - Pro Builder

Getting HVAC Right: Consider These Tips When Sizing and Specifying.

Posted: Fri, 05 Jan 2018 08:00:00 GMT [source]

3 DESIGN METHODS

Given the same duct size, airflow and velocity, the amount of friction loss (air resistance) in a flexible duct is about 35% more than a round rigid duct. This is before accounting for any compression that flexible ducts are susceptible to. Return duct sizes are primarily depending on the airflow of the HVAC unit which is corresponding to the tonnage or capacity of the HVAC unit. However, velocity is a critical factor as it affects the noise level. So, I made a return duct size chart as well as a guide on how to determine the right return duct size. At section 1, total pressure loss depends on the shape of the entry.

Types of Ducts in HVAC (Rigid, Kitchen, Fire & Pre-Insulated)

How to Size Duct in the Field - Contracting Business

How to Size Duct in the Field.

Posted: Fri, 11 Jun 2021 07:00:00 GMT [source]

Method of test to determine leakage of operating HVAC air distribution systems. E Collector manufacturers set fabric bag cleaning mechanism to actuate at a pressure difference of 750 Pa between inlet and outlet plenums. Pressure difference across clean media is approximately 400 Pa.

Then, we need to size and place the supply diffuser and return grille. After that, we can proceed to size the duct and design its path. Finally, we want to consider adding a fresh air duct and check the static pressure in the duct system.

HVAC Duct Design and the Importance of Return Air

Yes, if your house is either hot or cold, I'll bet you have inferior or lacking return air ducts. Blocking a return air vent disrupts the air pressure and flow within the HVAC system, leading to inefficiencies and potentially higher energy costs. I have to use return air ducts because I use one HVAC unit for the entire home and thus, there are multiple rooms to serve. Whenever you branch out a duct, minus the total airflow by the airflow going to the branch duct to reduce the size of the subsequent main duct and connect two different duct sizes with a duct reducer. The size of the main duct is based on the total airflow or the airflow rated on your HVAC unit. For duct sizing, you can use online calculators or see my post How to Calculate Duct Size?

What's the Best Location for Return Air Ducts?

Most of the time, central air conditioners in homes require ducted returns. When the branch duct reaches the end, I draw a curve line connecting the diffuser to the duct, indicating a flexible duct connection. As a general good practice, you should fix the height of the main duct to be about the same as the height of the HVAC unit. For instance, if your HVAC unit has a height of 250mm (10″), your main duct should also be 250mm (10″). As a reminder, you need to identify the size and type of the grille/diffuser before this step. Otherwise, you don’t know how many numbers of grille/diffuser you need for each room.

By guiding the height of the main duct, your ceiling height can be higher. Although square-shaped ducts are cheaper, they occupy more ceiling space and low ceiling height will make your home feel dark and cramped. Most HVAC units are designed to have a 400 CFM of airflow for every BTU or 1 ton of cooling capacity and BTU divided by 400 CFM is 30. Designing HVAC ductwork requires experience and broad knowledge about ducted air conditioning.

In practice, the airflow of your HVAC unit will vary based on many factors. Nonetheless, the duct size shown here should be able to handle them. These ducts pump air out of a room and send it back to the HVAC system, where it is filtered and reconditioned. This system allows the same air to be circulated throughout a building, which helps maintain a consistent temperature and promote air quality.

In other words, you must determine how fast heat is getting into your house and what things inside the house are contributing to heat gain. The single giant return air grill in the floor balances the load at the furnace motor but does nothing to promote cross-ventilation in each room. This, in turn, creates a greater suction in the rooms that really need cool air. This principle is no different than dampers which are used on supply lines to regulate airflow. If you live in a home that has rooms that are either too hot in hot weather or are cold in cold weather you could have a return-air duct issue. Some believe that closing off return vents in certain areas can enhance the system’s performance in heating or cooling other parts of the home.

Note that, for a loss coefficient less than one, static pressure upstream of the exit is less than atmospheric pressure (negative). Static pressure just upstream of the discharge fitting can be calculated by subtracting the upstream velocity pressure from the upstream total pressure. Below tables provide the possible return duct sizes for different HVAC units. The first size is the recommended size and the following two sizes are smaller. The corresponding velocity and friction loss are stated for all sizes. For flexible duct, the friction loss based on 0%, 5% and 10% compression are provided.